FunFlex Pilot Case introduction

Read the short story of the FunFlex Pilot Case lead by LEYGATECH that was selected through the FlexFunction2Sustain Open Call working on the surface functionalization of Circular flexible food packaging.

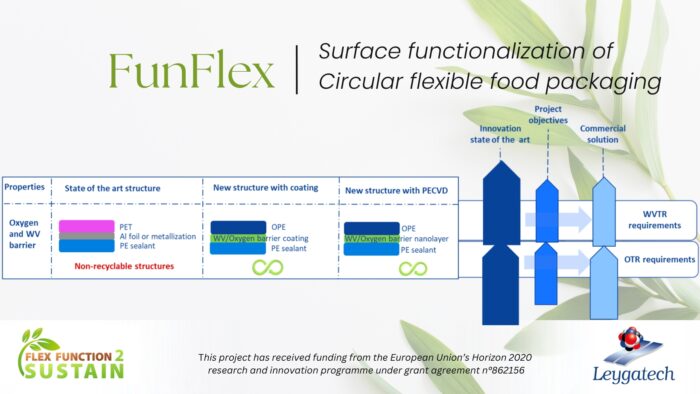

The EU Single Use Plastic directive or the French law AGEC is increasing pressure on the plastic converters, urging them make a quick response especially on the recyclability of single use plastic products. The FUNFLEX project aims at developing and implementing novel multilayer structures based on the use of advanced coating or nanolayer that ultimately will insure recyclability to single-use food packaging solutions. Using available surface treatment technologies, barrier capabilities will be brought to an eco-designed structure that is able to replace actual state of the art, unrecyclable, packaging. Should it be realized by means of coating or plasma deposition technology, these techniques still misses the final industrialization step. Finally, the developed solutions will undergo LCA studies as well as recycling and food contact certification to prove that they have a positive environmental impact and that they do not diminish the waste recovery efficiency. The achievement of the objectives will allow to demonstrate the feasibility of ready to recycle packaging for applications such as tray lids, snacks packaging, high output pouch making and many others. Those achievements will first insure a stronger competitiveness of the company but also insure the commercialization of products that would have been banned in 2025 if not recyclable.

In order to execute this Pilot Case, LEYGATECH is using the combined services of FlexFunction2Sustain consortium partners Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP and Fraunhofer Institute for Process Engineering and Packaging IVV, IPC – Centre Technique Industriel de la Plasturgie et des Composites, INL International Iberian Nanotechnology Laboratory & Sonnenberg Harrison Partnerschaft.

- Development of PE functionalization;

- Evaluation of the solutions and validation of the best structure;

- Compliance with standards, Food contact assessment and Intellectual Property analysis.

Further details on FunFlex Pilot Case development will follow. We promise to keep you posted on the progress!

.