Less Persistent Flexible Packaging – Procter & Gamble use case

Currently, flexible packaging used by typical Fast-Moving Consumer Goods (FMCG) businesses require a sufficient degree of water permeation barrier to enable a shelf life longer than 1 year; and sufficient mechanical strength to withstand the converting and sealing process – without damaging the barrier. This particular program pursued scale-up of a new barrier paper laminate structure which would have the properties above, but that would also be designed to be less persistent and recyclable in the paper stream.

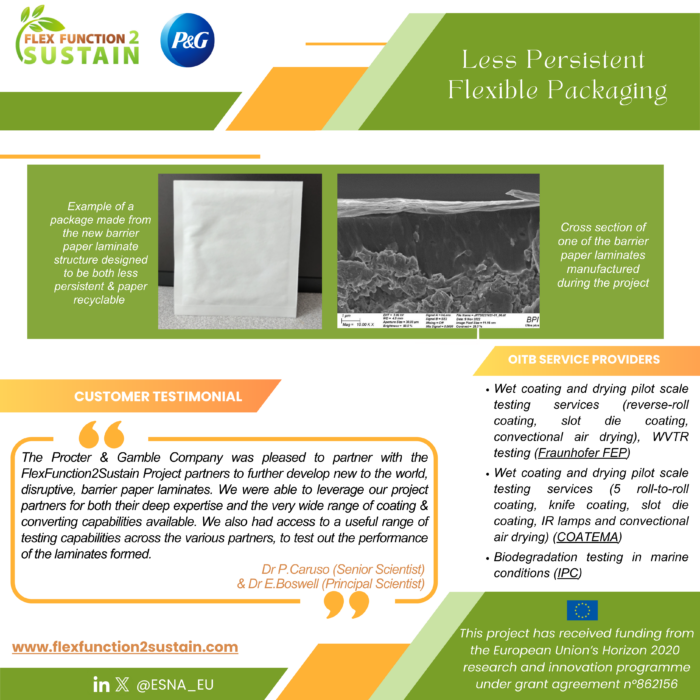

During the FlexFunction2Sustain project Procter & Gamble was able to run pilot scale trials with a large range of coating systems at the facilities of multiple project partners. In their Use Case, Procter & Gamble has unveiled a new barrier paper laminate structure that’s designed to be both less persistent and fully recyclable in the paper stream.

“The Procter & Gamble Company was pleased to partner with the FlexFunction2Sustain Project partners to further develop new to the world, disruptive, barrier paper laminates. We were able to leverage our project partners for both their deep expertise and the very wide range of coating & converting capabilities available. We also had access to a useful range of testing capabilities across the various partners, to test out the performance of the laminates formed.” says Dr Pier-LorenzoCaruso (Senior Scientist) & Dr Emily Boswell (Principal Scientist) at Procter & Gamble

Read the full story HERE.

.